Hardening service

Hardening services by a professional team with over 22 years of experience.

Why choose our hardening service

We prioritize the quality of our work and are committed to continuous improvement to provide the best service to all our customers.

We operate a modern, precise production control system and are certified to ISO 9001, IATF 16949, and CQI-9 standards.

Company Profile

Our Services

High carbon steels

High carbon steel contains approximately 0.6–1.5% carbon. It offers excellent strength and hardness but tends to be brittle and difficult to form. This type of steel is ideal for applications that require high hardness and wear resistance.

Medium carbon steels

Medium carbon steel contains approximately 0.3–0.6% carbon. It offers balanced strength and toughness and can be hardened and tempered to enhance its mechanical properties. This type of steel is suitable for applications requiring both strength and impact resistance.

Low carbon steels

Low carbon steel contains less than 0.2% carbon. It is known for its high toughness and ductility, but it has relatively low strength and hardness. It cannot be directly hardened unless it undergoes surface carburizing to increase carbon content at the surface. This type of steel is ideal for applications that require good formability.

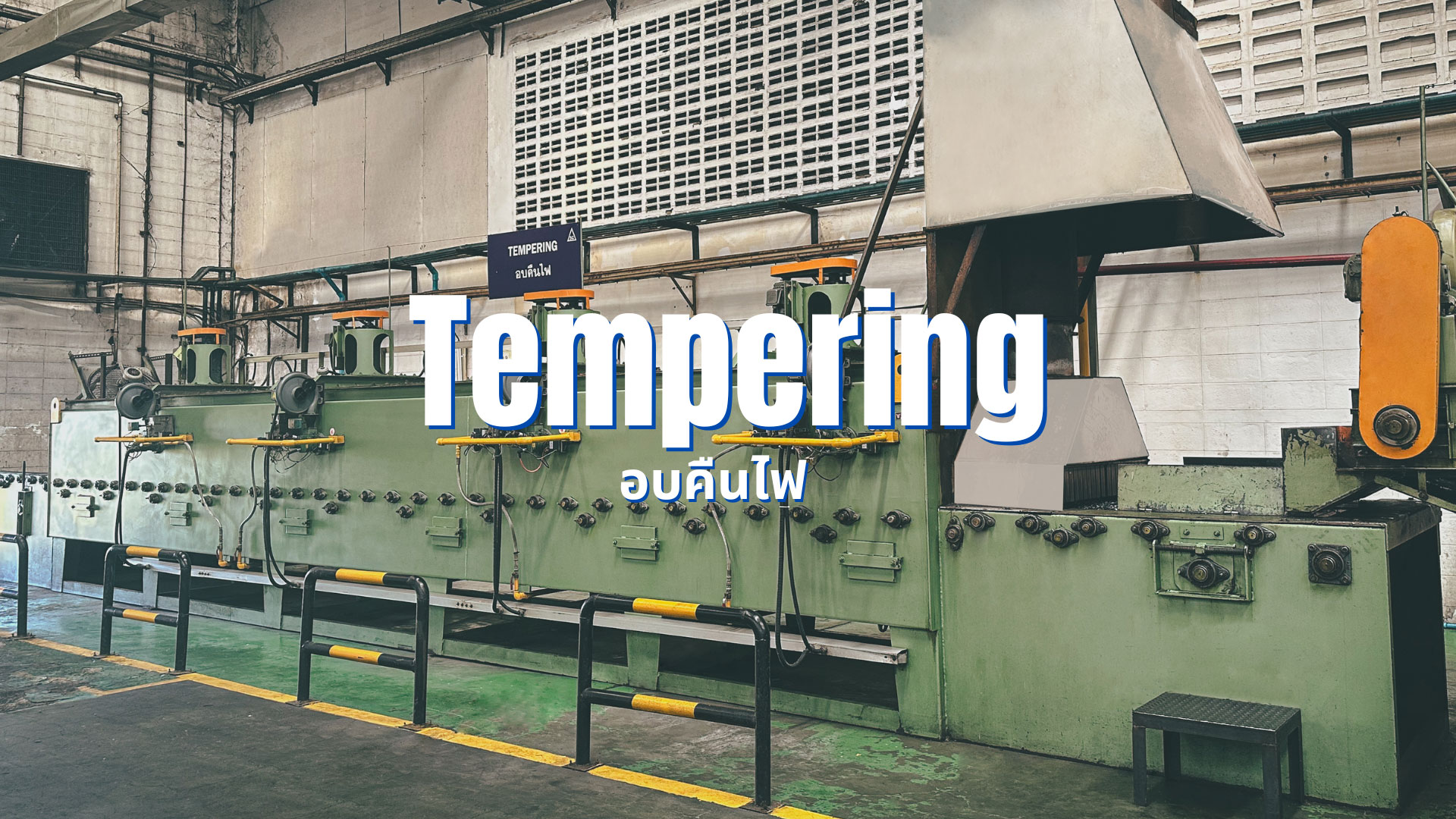

Tempering

Tempering is a heat treatment process applied to metals to improve their mechanical properties, reduce brittleness, and relieve internal stresses caused by prior hardening. It enhances toughness and increases resistance to fracture.

Shot blast

Shot blasting is a surface preparation process that involves propelling abrasive materials, such as sand or steel shots, at high pressure onto a workpiece. This abrasion effectively removes dirt, rust, old paint, and surface imperfections, leaving the surface clean and ready for further treatment.

Examples before and after

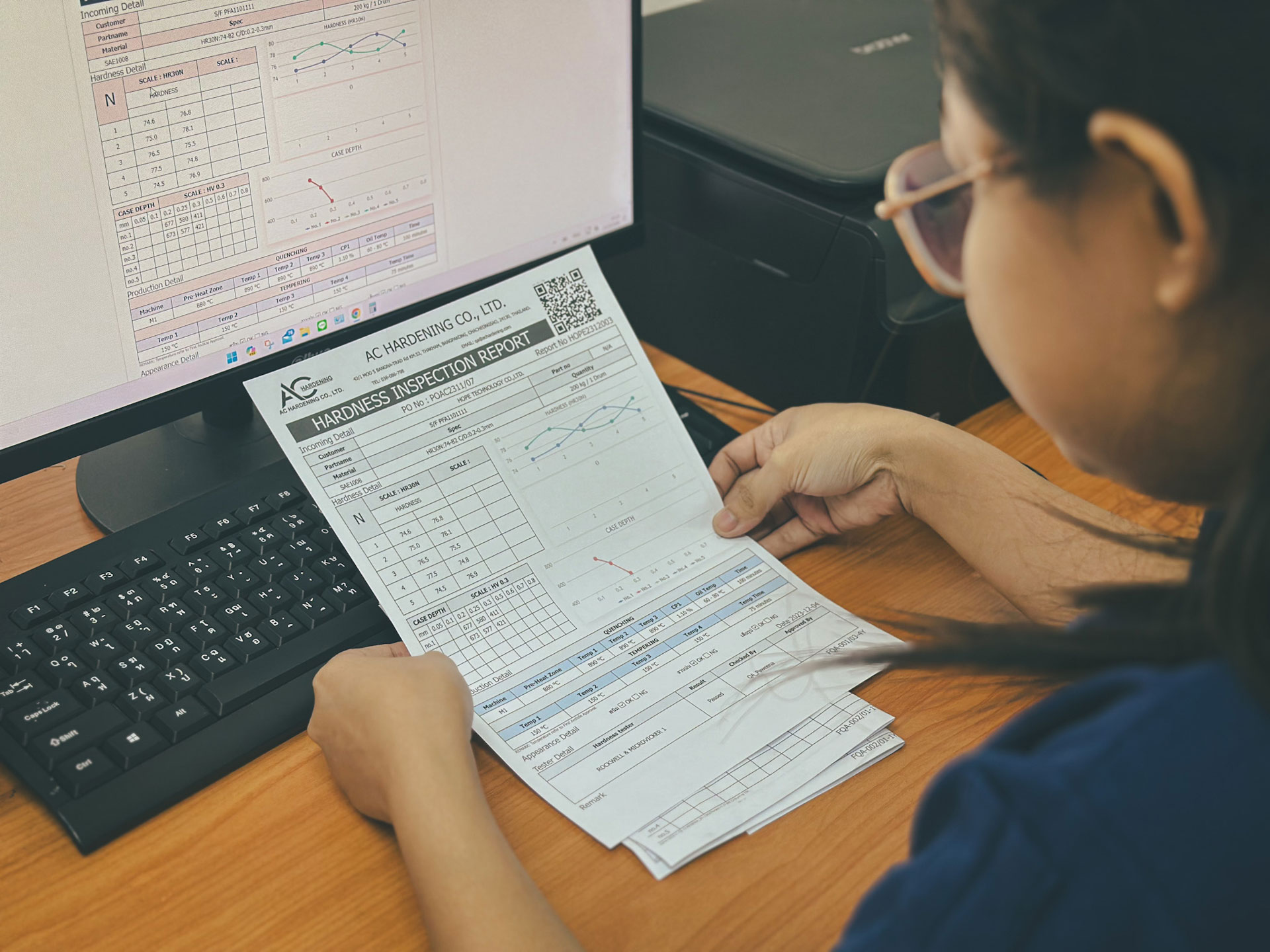

Hardness Rockwell

The Rockwell hardness test uses various scales—such as HRC, HRA, HRB, HR15N, and HR30N—to measure the hardness of different materials, not just steel. The test works by applying a specific load to an indenter, which is pressed into the surface of the material. The depth of the indentation, created under controlled force, is then measured and converted into a hardness value. This method is widely used due to its speed, simplicity, and versatility across different materials.

Micro vicker hardness (HV)

A Micro Vickers hardness tester is an instrument used to measure the hardness of materials by pressing a rectangular-based pyramid indenter (Vickers indenter) into the surface of a workpiece. A specified force, typically ranging from 100 gf to 1000 gf, is applied depending on the testing standard. The size of the resulting indentation is then measured, and the hardness value is automatically calculated.

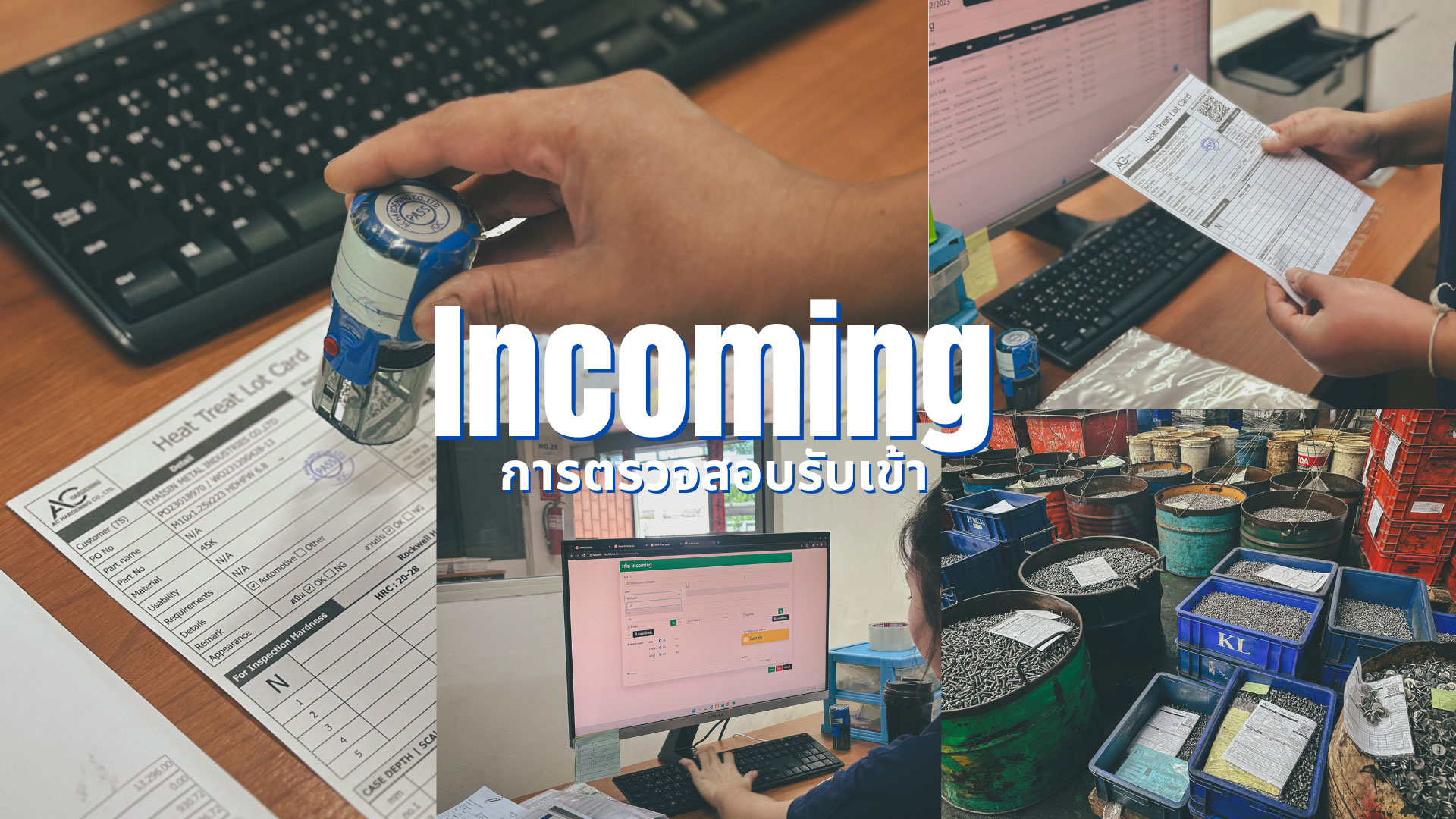

Flow process

Certificate

Our company is certified to ISO 9001 and IATF 16949,

and we implement the Special Process: Heat Treat System Assessment (CQI-9) to ensure quality and safety at every stage of production.

As a member of the Automotive Industry Action Group (AIAG),

we are committed to developing and upholding global standards in the automotive industry.

Our machines

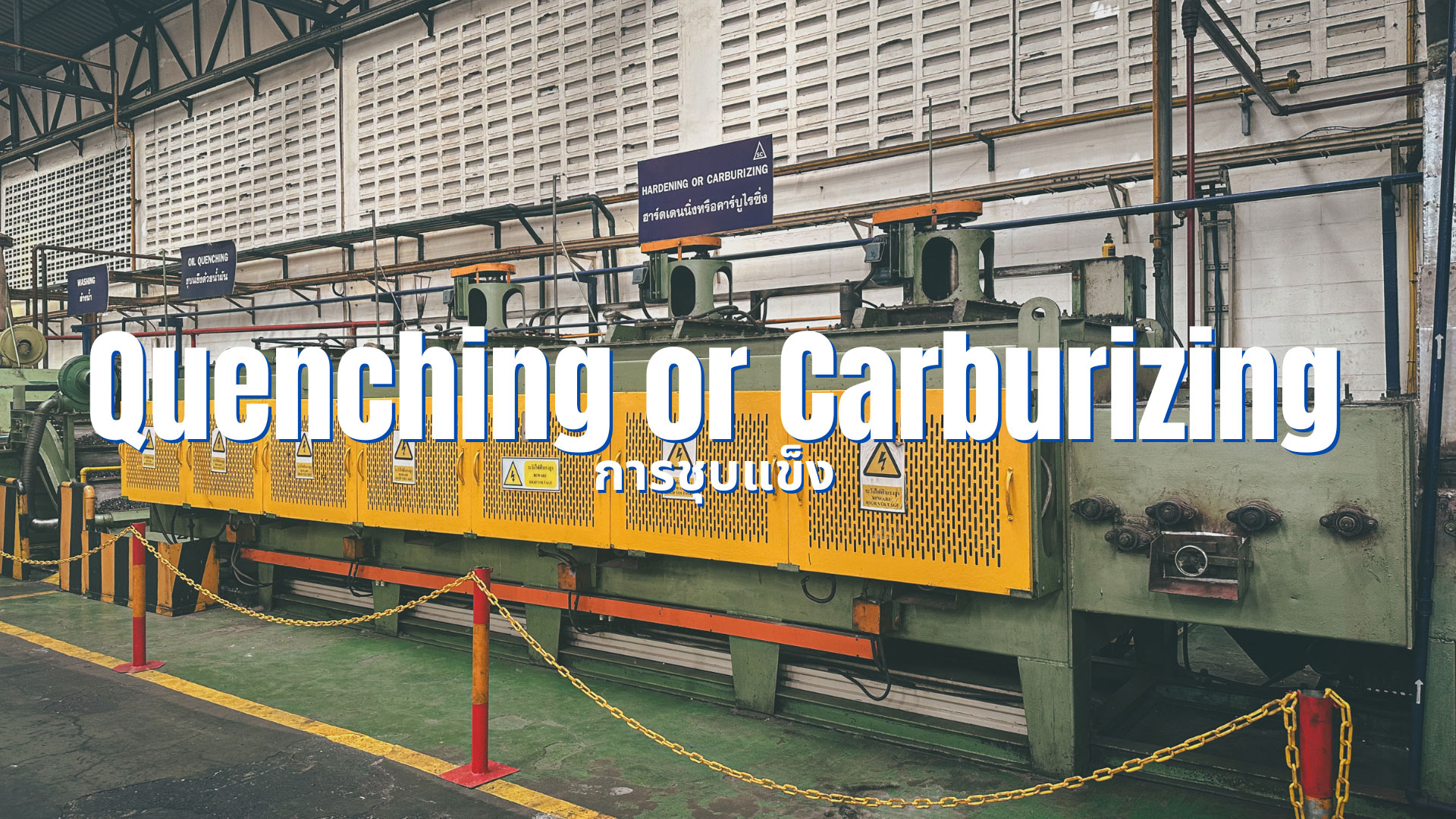

Mesh belt furnace M1

Our belt furnace oil quenching system is designed for continuous, high-volume heat treatment, making it ideal for small to medium-sized components such as nuts, bolts, screws, clips, and springs. 🔧 System Capabilities: The belt furnace supports two main heat treatment processes: Quenching & Tempering – Hardening process Carburizing & Tempering – Surface hardening (carburizing) process 📈 Production Capacity: Line M1: 3,000 – 5,000 kg/day 🛠️ Material Compatibility: Our oil quenching service is suitable for both carbon steel and low alloy steel components, including but not limited to: SWCH18A, SWCH22A, SCM435, S45C, SK5, SK85.

Mesh belt furnace M2

Our belt furnace oil quenching system is designed for continuous, high-volume heat treatment, making it ideal for small to medium-sized components such as nuts, bolts, screws, clips, and springs. 🔧 System Capabilities: The belt furnace supports two main heat treatment processes: Quenching & Tempering – Hardening process Carburizing & Tempering – Surface hardening (carburizing) process 📈 Production Capacity: Line M1: 5,000 – 8,000 kg/day 🛠️ Material Compatibility: Our oil quenching service is suitable for both carbon steel and low alloy steel components, including but not limited to: SWCH18A, SWCH22A, SCM435, S45C, SK5, SK85.

Shot blast machine

We provide sandblasting services for metal workpieces to effectively remove rust, scale, and surface contaminants. This process leaves the surface clean, smooth, and properly prepared for subsequent treatments such as hardening or coating. Sandblasting is ideal for small to medium-sized components, including: Nuts, bolts, screws, clips, springs, and other precision parts.

Cutting machine

A cutting machine used to prepare workpieces before hardness testing. It can cut metal workpieces accurately and efficiently.

Polishing machine

| A grinding machine used to prepare the surface of a workpiece before hardness testing. It polishes the metal surface to achieve smoothness for accurate and efficient testing. | |

|

|

Mounting press

A Mounting press used to prepare small workpieces before hardness testing. It ensures accuracy and precision during tests such as penetration hardness testing.

Where do we start?

-

2003 - AIK HONG HEAT TREATMENT (M) SDN BHD

In 2003, we began providing heat treatment services in Pekan Nanas, Johor, Malaysia, specializing in the heat treatment of carbon steel and alloy steel using a continuous belt furnace.

-

2014 - Established AC Hardening Co., Ltd.

Eleven years later, in 2014, we established AC Hardening Co., Ltd. in Thailand with the aim of expanding our metal hardening services and supporting the needs of customers in the automotive and other industries

-

2025 - Current

We continuously develop our production technology and services to deliver higher levels of customer satisfaction.

Our team

Ang wee peng

Founder

With over 22 years of metal headening experience in Malaysia, we are ready to develop and transfer that knowledge to our team to provide the best service to all customers.

Poramet Prombut

General Manager

A General Manager with deep expertise in engineering, production, and quality management, committed to driving continuous organizational improvement.

Patthawadee Phondongnok

Factory Manager

With in-depth experience in ISO 9001, IATF 16949, and CQI-9 standards, bringing professional expertise to uphold quality and safety throughout the entire production process.

Hardness Conversion

FAQ

Contact

Office

42/1 Moo 5 Bangna-Trad Road 53th KM, Tha Kham, Bang Pakong District, Chachoengsao 24130

Line AC Hardening

Tel +66 38 086-798

Email info@achardening.com